In the bustling world of fashion and manufacturing, success hinges on seamless communication. Imagine a designer with a brilliant new collection, eager to bring their vision to life. They’ve chosen a trusted supplier and nearby factories to help turn sketches into reality. But amid tight deadlines and complex logistics, small miscommunications can snowball into costly delays. Sound familiar?

This story isn’t unique; it’s a challenge faced by many companies striving to stay competitive in a fast-paced industry. Improving communication and collaboration with suppliers and factories isn’t just an operational necessity—it’s the backbone of a resilient, innovative supply chain.

The importance of clear communication

Every successful project starts with clarity. When suppliers and factories understand your design details, quality standards, and delivery timelines, the chances of errors diminish. Misunderstandings about fabric choices, sizing, or production schedules can cause delays and rework—costing time and money.

Moreover, transparent communication builds trust. When both parties are kept in the loop, cooperation becomes smoother, fostering long-term partnerships rather than transactional relationships.

Overcoming common barriers

While the desire to collaborate effectively is universal, several barriers can stand in the way:

- Geographical distances: Global supply chains mean teams are often split across different time zones, making real-time communication difficult.

- Language differences and cultural gaps: Variations in language and workplace culture can lead to misinterpretations.

- Fragmented information systems: Different teams may use different tools, leading to disjointed data and missed updates.

- Lack of visibility: Without real-time data, suppliers and factories operate on outdated information, increasing errors.

Strategies to enhance communication and collaboration

To overcome these hurdles, companies are adopting innovative strategies:

- Implement centralized communication platforms: Using shared digital platforms ensures everyone accesses the same, up-to-date information.

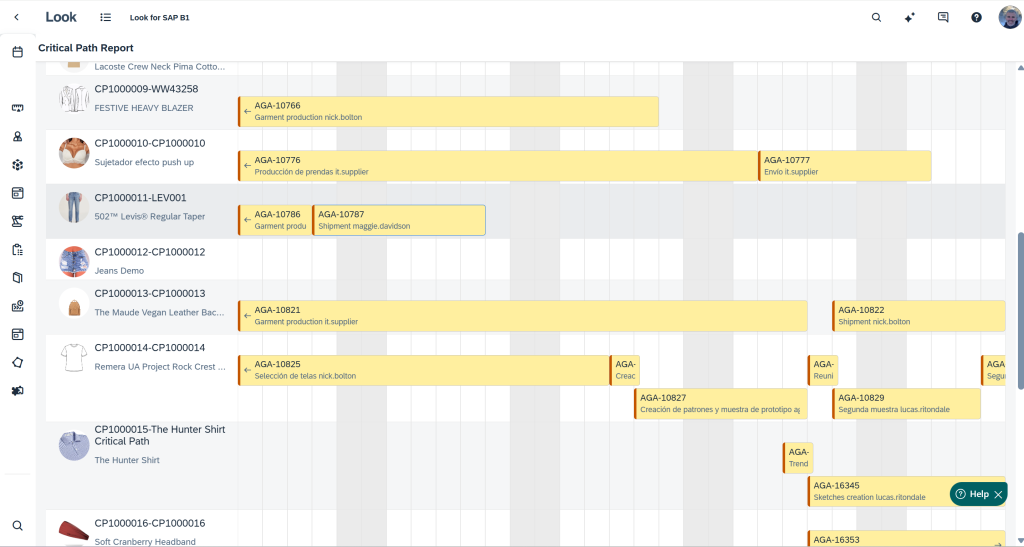

- Leverage real-time data sharing: Instant updates on orders, inventory, and production status help to synchronize efforts across the supply chain.

- Encourage open dialogue and feedback: Establish channels where suppliers and factories can voice concerns, ask questions, and suggest improvements.

- Standardize processes: Clear, consistent procedures help reduce misunderstandings and streamline workflows.

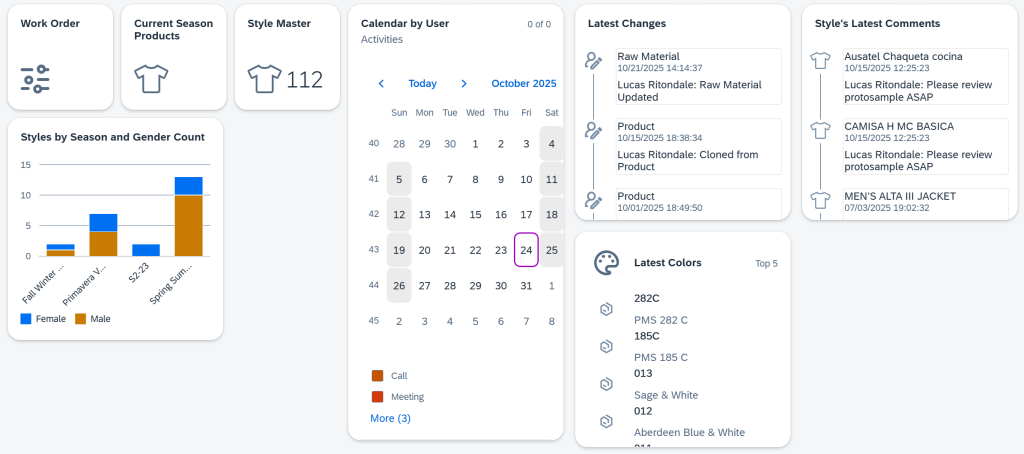

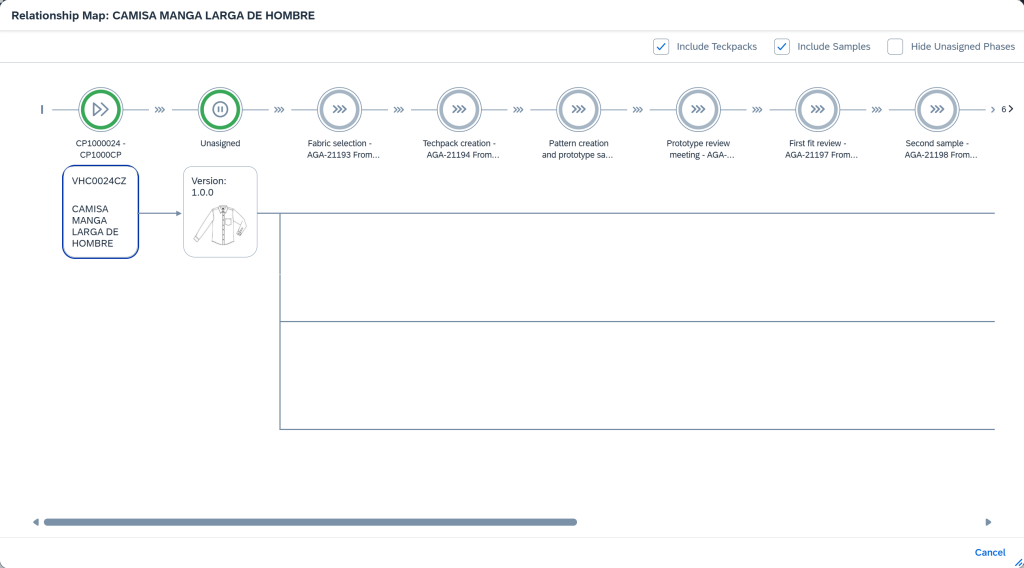

- Utilize visual management tools: Dashboards, charts, and visuals make complex data easier to understand and quicker to act on.

The role of technology in transforming supply chain collaboration

Technology has become a game-changer. Cloud-based platforms, AI-driven analytics, and mobile apps are streamlining interactions, providing transparency, and empowering decision-making.

Here’s where Look Cloud Fashion Platform makes a difference. Designed specifically for fashion brands and manufacturers, it offers a comprehensive solution that brings all parties onto a single, intuitive platform.

How Look Cloud Fashion Platform can help

Look Cloud Fashion Platform is more than just a management tool—it’s a bridge that connects brands, suppliers, and factories seamlessly. Here’s what it brings to the table:

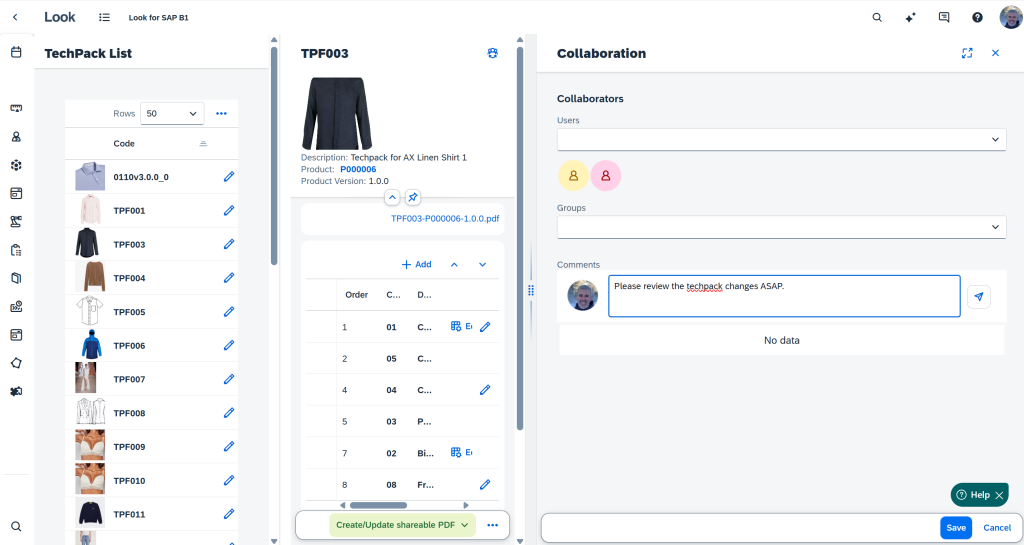

Centralized communication: All project data, conversations, and updates are stored in one accessible location, reducing miscommunication.

Real-time collaboration: From order placement to production tracking, everyone stays informed with live data.

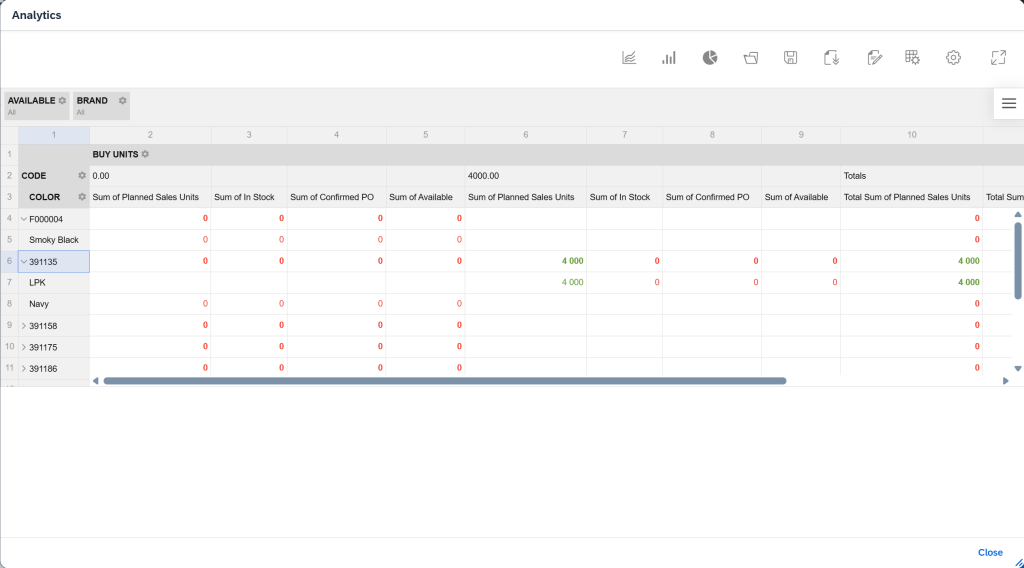

Visual tools: Interactive dashboards and product images help clarify specifications and reduce errors.

Workflow automation: Automation of routine tasks frees up time for creative and strategic activities.

Analytics and insights: Data-driven insights help identify bottlenecks and opportunities for improvement.